What are the characteristics and application advantages of hybrid ceramic bearings?

2023-10-11

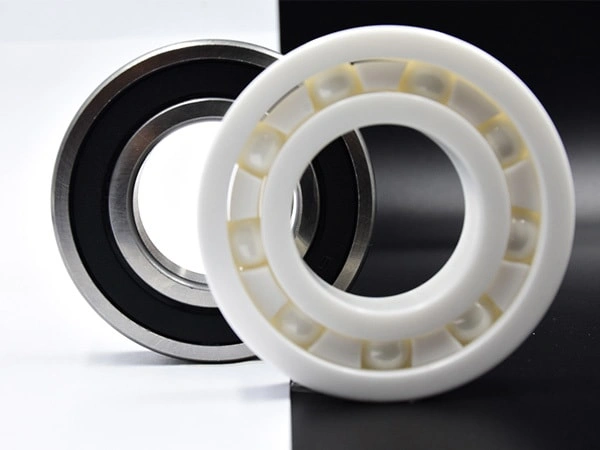

Due to the high elastic modulus of ceramics, the contact surface of hybrid ceramic bearings is smaller, which is beneficial to reducing rolling and sliding friction. In addition, the density of ceramics is lower than that of steel, so the centrifugal force is smaller, thus reducing friction at high speeds. In high-speed applications, axial preload is typically added to the bearing arrangement. In this case, deep groove ball bearings work on the principle of angular contact ball bearings; therefore, at high speeds, friction can be reduced to a more ideal level. Less friction means lower operating temperatures and longer lubricant life. Therefore, hybrid ceramic bearings are ideally suited for high-speed applications. Even in the case of insufficient lubrication, there will be no wear problem between silicon nitride and steel, so hybrid ceramic bearings can still run for a long time in the case of poor lubrication. For hybrid ceramic bearings, hybrid ceramic bearings may still perform well when some media that only form a very thin lubricating film, such as refrigerants, are used as lubricants. The hardness and elastic modulus of silicon nitride are higher than ordinary bearing steel, so the bearing has higher stiffness and can have a longer working life in polluted environments.

2023-10-11

Fix the inner ring and outer ring of the rolling element on the shaft or bearing box. When it is under load, the matching surface of the ring and the shaft or bearing box will not undergo relative movement in the radial, axial and rotational directions. This This relative motion will cause friction, friction corrosion or friction cracks on the mating surface, causing damage to the bearing, shaft and bearing box, and then the wear powder will mix into the inside of the bearing, causing poor operation, abnormal heating or vibration. .

Material properties of silicon nitride ceramic bearings

2023-10-11

As an excellent high-temperature engineering material, Si3N4 ceramic material can best exert its advantages in its application in high-temperature fields. The future development direction of Si3N4 is: ⑴ Give full play to and utilize the excellent characteristics of Si3N4 itself ⑵ When sintering Si3N4 powder, develop some new fluxes and study and control the optimal composition of existing fluxes. ⑶Improve powdering, molding and sintering processes

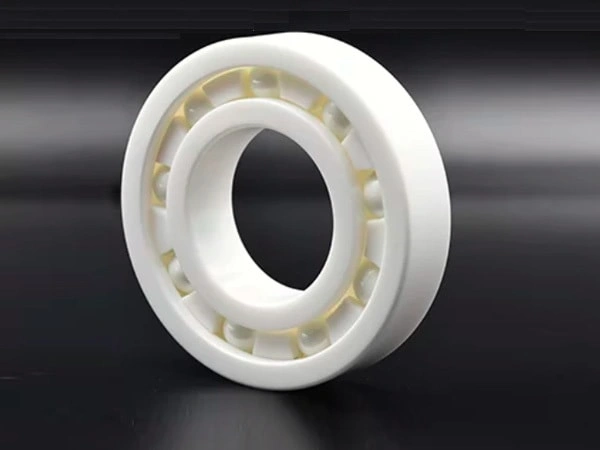

Product introduction of deep groove ball ceramic bearings

2023-10-11

POM (polyoxymethylene) operating temperature range is from - 60°C to 100°C. Due to its high surface strength and smoothness, POM has excellent sliding properties and wear resistance. POM basically does not experience tension, and its copolymer has high thermal stability and chemical stability (it is worth paying special attention to its enhanced hydrolysis resistance) PA polyamide (nylon) is a high-precision engineering plastic, and polyamide has High strength, hardness and toughness, as well as high heat resistance and non-deformation (about 40°C to 100°C). Since good mechanical properties can only be achieved after the material temperature is suitable, it must be humidified again after annealing and grown in the air. Time storage can also reach the corresponding temperature.

Ceramic bearing material classification

2023-10-11

All-ceramic bearings have the characteristics of anti-magnetic and electrical insulation, wear resistance and corrosion resistance, oil-free self-lubrication, high temperature resistance and high cold resistance, and can be used in extremely harsh environments and special working conditions. The ferrules and rolling elements are made of zirconia (ZrO2) ceramic material, and the cage is made of polytetrafluoroethylene (PTFE) as standard configuration. Generally, glass fiber reinforced nylon 66 (RPA66-25), special engineering plastics (PEEK, PI), stainless steel (AISISUS316), brass (Cu), etc.

2023-10-11

Ceramic materials are the materials with the best stiffness and highest hardness among engineering materials, and their hardness is mostly above 1500HV. Ceramics have high compressive strength, but low tensile strength, and poor plasticity and toughness.

Type characteristics of zirconia ceramic bearings

2023-10-11

Pure ZrO2 is white, and appears yellow or gray when containing impurities. It generally contains HfO2 and is difficult to separate. The world's proven zirconium resources are about 19 million tons, and zirconium oxide is usually produced by purifying zirconium ore. There are three crystal states of pure ZrO2 under normal pressure: monoclinic zirconia (m-ZrO2), tetragonal zirconia (t-ZrO2) and cubic (Cubic) zirconia (c-ZrO2). Types exist in different temperature ranges and can be converted into each other:

Silicon nitride full ceramic bearing application classification

2023-10-11

High-speed bearings: They have the advantages of cold resistance, low stress elasticity, high pressure resistance, poor thermal conductivity, light weight, and small friction coefficient. They can be used in high-speed spindles of 12,000 rpm-75,000 rpm and other applications. In high-precision equipment;