Material properties of silicon nitride ceramic bearings

2023-10-11

As an excellent high-temperature engineering material, Si3N4 ceramic material can best exert its advantages in its application in high-temperature fields. The future development direction of Si3N4 is: ⑴ Give full play to and utilize the excellent characteristics of Si3N4 itself ⑵ When sintering Si3N4 powder, develop some new fluxes and study and control the optimal composition of existing fluxes. ⑶Improve powdering, molding and sintering processes

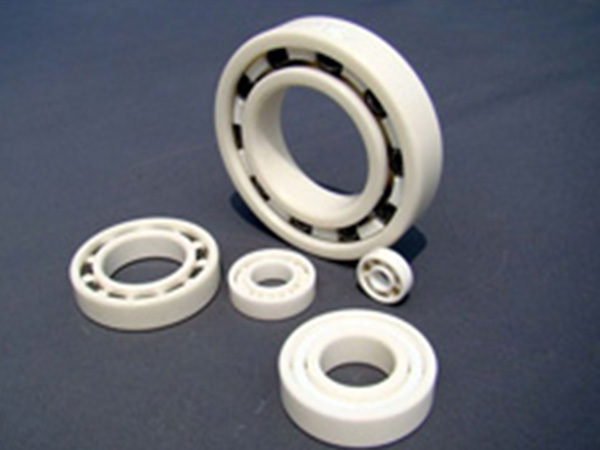

Ceramic bearing material classification

2023-10-11

All-ceramic bearings have the characteristics of anti-magnetic and electrical insulation, wear resistance and corrosion resistance, oil-free self-lubrication, high temperature resistance and high cold resistance, and can be used in extremely harsh environments and special working conditions. The ferrules and rolling elements are made of zirconia (ZrO2) ceramic material, and the cage is made of polytetrafluoroethylene (PTFE) as standard configuration. Generally, glass fiber reinforced nylon 66 (RPA66-25), special engineering plastics (PEEK, PI), stainless steel (AISISUS316), brass (Cu), etc.

2023-10-11

Ceramic materials are the materials with the best stiffness and highest hardness among engineering materials, and their hardness is mostly above 1500HV. Ceramics have high compressive strength, but low tensile strength, and poor plasticity and toughness.

Type characteristics of zirconia ceramic bearings

2023-10-11

Pure ZrO2 is white, and appears yellow or gray when containing impurities. It generally contains HfO2 and is difficult to separate. The world's proven zirconium resources are about 19 million tons, and zirconium oxide is usually produced by purifying zirconium ore. There are three crystal states of pure ZrO2 under normal pressure: monoclinic zirconia (m-ZrO2), tetragonal zirconia (t-ZrO2) and cubic (Cubic) zirconia (c-ZrO2). Types exist in different temperature ranges and can be converted into each other:

What are the benefits of using the characteristics of ceramic bearings?

2023-10-11

Ceramic bearing manufacturers Ceramic bearings have the characteristics of high temperature resistance, cold resistance, wear resistance, corrosion resistance, antimagnetic electrical insulation, oil-free self-lubricating, high speed and other characteristics. It can be used in extremely harsh environments and special working conditions, and can be widely used in aviation, aerospace, navigation, petroleum, chemical industry, automobiles, electronic equipment, metallurgy, electric power, textiles, pumps, medical equipment, scientific research and national defense and military fields. High-tech products using new materials.

Application characteristics of ceramic bearing materials

2023-10-11

Ceramic bearings are a general term and can be subdivided into two types: full ceramic bearings and hybrid ceramic bearings (semi-ceramic bearings). Common ceramic materials in bearings include silicon nitride, aluminum oxide, zirconia and silicon carbide.